Phase02

PACKAGING

-

Primary Packaging: It is the container aimed at containing a product and which is contact with it.

-

Secondary Packaging: It is the container used to contain primary packaging.

-

Packaging Materials: They are all the materials, procedures and methods used to condition, present, handle, store, preserve and transport goods.

Table Eggs

Eggs shall comply with the applicable standards, laws and regulations –which define the criteria for quality, weight, freshness, packaging and labeling– to be marketed and exported/imported.

Eggs are packaged after they have been classified and graded. External packaging materials of eggs shall be new, shock-resistant, dry, clean and in good condition. Usually, these materials protect eggs from off-odors and of possible quality alterations –moderate pulp, cardboard or polyethylene.

Eggs should be sold to consumers during the 21 days after it was laid, even though they can be consumed until the best-by date on the package, which is by the 28th day after they were laid.

a) Bulk and Wholesale.

Eggs intended to be sold bulk or wholesale are placed in polyethylene, cardboard or molded pulp cartons, boxes or trays where they can be transported without moving. Eggs are commonly contained in packages of 24 or 30 pieces according to t label is placed on the outside he supplier. These are in turn packaged in cardboard boxes which protect against shocks. Boxes are sealed, adhesive tape is used and a fully identifying information label is placed on the outside. Box resistance should be capable of withstanding the stacking height without deformations.

b) End-consumer and Retail.

Eggs intended for retail are placed in plastic or cardboard cartons, boxes or trays that can hold eggs without movement. Eggs are commonly contained in packages of 6, 12 or 18 pieces according to the suppliers. They are also packaged in cardboard boxes which protect against shocks.

Egg Products.

-

Egg products should be packaged in containers made with safe and resistant materials for the different process steps, so that they do not react with the product or alter its physical, chemical, sensory and microbiological characteristics.

-

External packaging materials should be new, resistant offering appropriate protection for packages to prevent their external deterioration, as well as facilitating handling, storage and distribution.

-

Egg products shall be transported and stored in optimum conditions for preservation and safety in the entire logistics chain, from its point of origin to its final destination. Therefore, physical presentation, arrangement, packaging, external packaging and materials used are of utmost importance to prevent issues when entering into Mexico.

-

Eggs or egg products shall be transported at the right temperature according to the type of goods and their presentation (dried, fresh-refrigerated or frozen). For this reason, it is key to have compact, quality packaging materials which offer maximum strength under humid conditions.

-

Usually, cardboard packaging materials are most commonly used for this type of goods, keeping in mind that it is 100% recyclable.

-

High resistance to humidity makes compact cardboard to be suitable for storage and transportation of goods under refrigeration or freezing.

-

Production and marketing of egg derivatives has made progress recently due to the evolution of the food industry which increasingly demands raw materials and ingredients meeting its needs.

-

Manufacturing, marketing and use of egg products meets community regulations on food hygiene, product quality, labeling and destination.

-

Once the package is open, they shall be used immediately and never be left at room temperature.

a) Bulk and Wholesale.

Egg products sold bulk or for wholesale (dried or dehydrated eggs) are placed in plastic bags contained in cardboard boxes or in bags protecting them against shocks, jerks or tipping over. Cardboard boxes are sealed, adhesive tape is used and a fully identifying information label is placed on the outside. Box resistance should be capable of withstanding the stacking height without deformations. On the other hand, bags are closed and the label is placed on the outside with fully identifying information. Stable (dehydrated or dried) products can be kept at room temperature.

b) End-Consumer and Retail

Egg (dried or dehydrated) products aimed at retail or end-consumers are placed in food-grade bags or plastic cans contained in cardboard boxes protecting against shocks, jerks or tipping over. Stable (dehydrated or dried) products can be kept at room temperature.

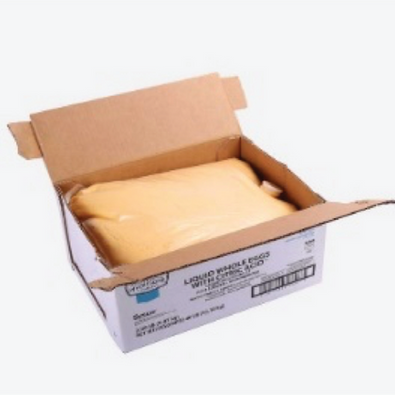

c) Bulk and Wholesale

Egg products to be sold in bulk or for wholesale (liquid frozen eggs) are placed in plastic bags contained in cardboard boxes or in plastic cans of approximately 14 kgs. (30.8 lbs.) protecting from shocks, jerks or tipping over. Boxes are sealed, adhesive tape is used and a fully identifying information label is placed on the outside. Box resistance should be capable of withstanding the stacking height without deformations. On the other hand, plastic cans are closed and the label is placed on the outside with fully identifying information. Storage temperature of this product shall be kept between 0-4 °C (32-39 °F).

d) End-Consumer and Retail.

Egg products to be sold to end-consumers or at retail (liquid frozen eggs) are placed in food-grade plastic bags contained in cardboard boxes protecting from shocks, jerks or tipping over.

It must be taken into account that for all egg products, table eggs, to be sold to end-consumers or at retail, boxes are sealed, adhesive tape is used and a fully identifying information label is placed on the outside in accordance to NOM-051-SCFI/SSA1-2010 Mexican Official Standard. Box resistance should be capable of withstanding the stacking height without deformations.

Hatching Eggs.

Hatching eggs exported and intended for a hatchery in Mexico are usually placed on cardboard cartons or trays protecting them from shocks or jerks. These cardboard trays are placed onto plastic bases, and the bases are stack on one another. They shall be resistant enough to withstand the stacking height without deformation. After these bases are stacked, they are normally put inside a cardboard box, and the cardboard boxes are closed and wrapped in plastic or protected with several plastic layers around to avoid movement among boxes. External packaging materials for eggs shall be new, dry, clean and in good condition.

It is important to have the same ambient/temperature condition between the truck and the farm’s egg warehouse to preserve the potential growth.

Shocks between carts/egg tray towers, strong jerks and sudden movements should be avoided; trucks shall have a good suspension system and fix carts/tower of trays well. Access to the hatcheries shall be in the best possible condition.

It is key to use temperature monitors during transportation to check for temperature fluctuations during that period. Also, it is recommended to measure the external and internal temperature of several eggs in different locations to verify temperatures.

Cleaning and disinfection of all components involved in transportation of eggs is of utmost importance to avoid pathogen dissemination.

If truck temperature is greater than the farm’s warehouse temperature, there is a risk of egg’s “perspiration” (condensation formed when the colder egg surface is exposed to warmer and/or more humid air).

When the temperature is the same in both areas, the same “perspiration” may happen during loading or unloading if the environment is excessively humid. In such an instance, it is recommended to increase warehouse temperature from the recommended 18-20 ⁰C (64-68 ⁰F) to 23 ⁰C (73 ⁰F), or to preheat them to this same temperature of 23 ⁰C (73 ⁰F) for four hours before eggs will be transported.

Birds of up to Three Days of Age.

Newly born birds of up to three days of age intended for a broiler barn in Mexico, usually are placed in plastic trays or boxes protecting them from shocks or sudden movements. They are stacked on one another, and should perfectly fit to have stacking uniformity, and no voids among them, so birds cannot stick out their heads or get out. Carrying trays shall be dry, clean, in good condition and resistant to shocks. No feed, water, bedding, pads or any accessory or material different from chicks may be entered into Mexico.

Transportation of one-day chicks from the hatchery to the farms is a key step in the broiler productive cycle. The best possible conditions should be made available, and fully monitor all parameters that can have influence both on the well-being of chicks, as well as on the beginning and future zootechnical results of lots.

If transportation conditions are not optimum, stress will translate into a bad development affecting immunity, initial feed consumption and digestion, consistency and weight gain and, in the worst-case scenario, leading to mortality.

One-day old chicks are by nature well suited for transportation. They are born with yolk residue, and are comfortable without feed or water for up to two days, as long as the thermal neutrality zone is maintained in the boxes. In this narrow temperature range of 32-35 ⁰C (90-95 ⁰F), their metabolism is only for maintenance with a minimum heat production and water loss.

If temperature in the boxes increases over this range, chicks will start to use energy of the is vitelline vesicle at a much faster pace, so they do not have to pant and try to maintain their optimum body temperature between 40.0 and 40.5 °C (104 and 104.9 °F).

Thus, the following items are to take into account:

-

It is important to optimize the transportation conditions from the hatchery to the barn for later yields. It is not appropriate to evaluate only the packaging materials and transportation based on the number of dead chicks upon arrival.

-

100% of the checklist items shall be met for transportation and packaging materials conditions, starting with sanitary and cleanliness conditions, followed by ventilation, structure, engines, capacity and maintenance.

-

Choose chick transportation trucks that are reliable, capable of operating in the range of extreme conditions due to weather, in the geographic location of your hatchery and your clients’.

-

Keep a temperature from 32 a 35 °C (90 to 95 °F) inside the chicks’ boxes, optimizing air temperature and speed.

-

Work fast during the critical loading and unloading process when there is not forced-air ventilation, and/or provide sufficient spacing between chick individual boxes or trays.

-

Consider the location of temperature monitors while reviewing the exit. Avoid direct contact between chicks and sensors.

-

Adjust the number of chicks per box or tray, if not done, the optimum temperature in the transportation boxes cannot be achieved.

Pallets.

It is important to use pallets or stacked product which facilitates loading and unloading of goods. If pallets are made of debarked wood, they shall bear the official stamp indicating they were subjected to treatment against pests using methyl-bromide fumigation with a total 24-hour exposure, heat treatment or sulfuryl fluoride in accordance to NOM-144-SEMARNAT-2012 Mexican Standard –which sets forth the phytosanitary measures to reduce the risk of introduction and/or spreading of quarantine pests associated to international trade mobilization of wood packaging material, made of raw wood used in international trade).

Regulations on International Trade Wood Packaging Material:

http://www.fao.org/3/a-mb160e.pdf

NOM-144-SEMARNAT-2012:

http://www.dof.gob.mx/nota_detalle.php?codigo=5264439&fecha=16/08/2012

Mark on wooden pallets:

Examples of Correct and Incorrect Loads.

Correct Loads:

Incorrect Loads: